Products Center

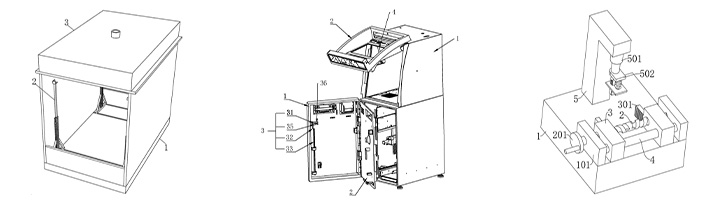

KNT Sheet Metal Fabrication specializes in customized production, With advanced laser cutting, CNC bending, and precision welding,Sheet metal processing that can handle complex bends and shapes,Can handle a variety of metal materials and surface treatments

· Mainstream: Carbon steel, galvanized steel, stainless steel, and aluminum alloy.

· Other: Brass, copper, titanium alloy (depending on laser power).

· High precision (±0.1mm): Smooth cuts and accurate dimensions.

· High flexibility: No molds needed, can quickly process any complex shape.

· High efficiency: Fast and highly automated.

· High material utilization: Intelligent software optimizes material usage.

· Small heat-affected zone: Minimal impact on the overall performance of the plate.

Best materials: low-carbon steel, galvanized steel, stainless steel, aluminum alloy (good bending performance).

· High precision (±0.1mm, ±0.5°): Ensures product fit and consistency.

· Complex shapes: Can handle multiple bends, rolling, and hemming.

· High efficiency: CNC programming for high speed.

· Springback control: Using angle compensation and other technologies.

· Large-size processing: Can handle workpieces up to several meters long.

· Welding: Carbon steel, stainless steel, and aluminum alloys (requires special welders/processes like MIG/TIG) are most common.

· Riveting/Screwing: Works for almost all combinations of metal sheets that can be drilled/tapped.

· Strong and reliable: Welding forms a permanent, high-strength connection.

· Highly automated: Robotic welding ensures high efficiency and stable quality.

· Good sealing: Can meet airtight and watertight requirements (e.g., fuel tanks, water tanks).

· Strong adaptability: Can connect metal parts of different thicknesses and shapes.

· Comprehensive processes: Proficient in welding various materials (stainless/carbon steel, aluminum) with continuous, intermittent, spot, and TIG welding.

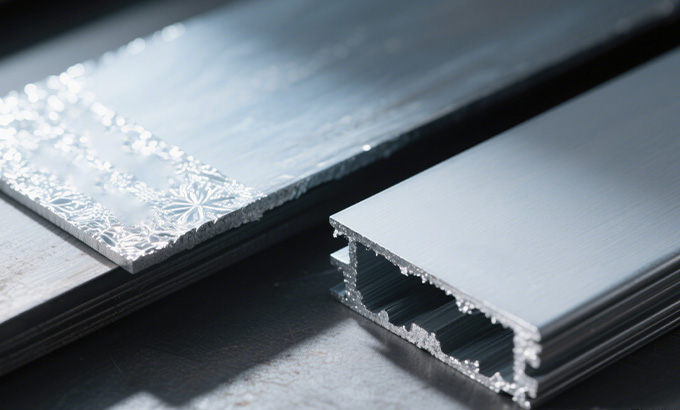

Applicable Metals: Aluminum, copper, stainless steel, etc.

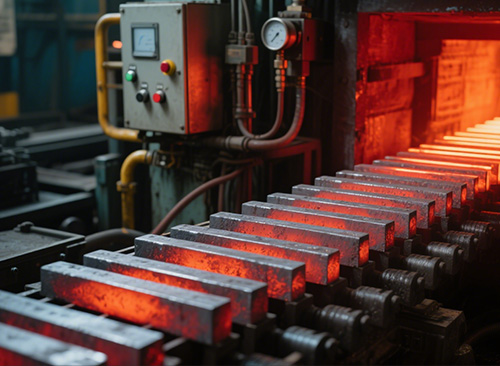

· High-efficiency mass production: Continuous automated processing is fast, suitable for large-volume production, and low cost.

· Stable precision: Cross-section dimensional tolerance within ±0.1mm, good straightness, and reduced springback deviation.

· Wide material adaptability: Cold work hardening can improve hardness and fatigue resistance.

· Flexible design: Can form complex cross-sections (e.g., C-shaped steel, special-shaped grooves), and changing rollers allows for shape adjustment with low modification costs.

Steel, stainless steel, aluminum, copper, etc.

· High-precision processing, suitable for complex geometric shapes.

· Can perform multi-directional processing, with high precision and surface quality.

· High finish.

Our engineers provide material recommendations based on your product's function, environment, budget, and appearance.

We offer various surface treatments to enhance corrosion resistance, durability, appearance, and function.

![]()

Painting/Powder Coating

![]()

Electroplating

![]()

Brushing/Polishing

![]()

Anodizing

![]()

Hot-dip Galvanizing

![]()

Passivation/Phosphating

![]()

Sandblasting

![]()

Carburizing

Our custom sheet metal services comply with ISO 2768-m to ensure precision and functionality.

| Dimension Details | Metric Units | Imperial Units |

|---|---|---|

| Edge to edge, single surface | ±0.127 mm | ± 0.005 in |

| Edge to hole, single surface | ±0.127 mm | ± 0.005 in |

| Hole to hole, single surface | ±0.127 mm | ± 0.005 in |

| Bend to edge/hole, single surface | ±0.254 mm | ±0.010 in |

| Edge to feature, multiple surfaces | ±0.762 mm | ± 0.010 in |

| Overmolded part, multiple surfaces | ±0.762 mm | ± 0.030 in |

| Bend Angle | ± 1° | |

Sharp edges are deburred by default. Specify on your drawing if an edge must remain sharp.

Note: Please leave your mobile phone number, our professionals will contact you as soon as possible!

Upload drawings

Upload drawings to get detailed quotation reply

All uploads are secure and confidential