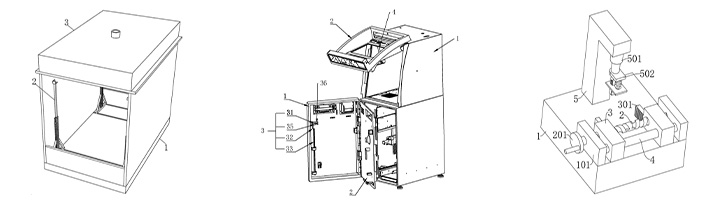

Custom sheet metal fabrication services

KNT Sheet Metal Fabrication specializes in customized production, With advanced laser cutting, CNC bending, and precision welding,Sheet metal processing that can handle complex bends and shapes,Can handle a variety of metal materials and surface treatments

· Mainstream: Carbon steel, galvanized steel, stainless steel, and aluminum alloy.

· Other: Brass, copper, titanium alloy (depending on laser power).

· High precision (±0.1mm): Smooth cuts and accurate dimensions.

· High flexibility: No molds needed, can quickly process any complex shape.

· High efficiency: Fast and highly automated.

· High material utilization: Intelligent software optimizes material usage.

· Small heat-affected zone: Minimal impact on the overall performance of the plate.

Best materials: low-carbon steel, galvanized steel, stainless steel, aluminum alloy (good bending performance).

· High precision (±0.1mm, ±0.5°): Ensures product fit and consistency.

· Complex shapes: Can handle multiple bends, rolling, and hemming.

· High efficiency: CNC programming for high speed.

· Springback control: Using angle compensation and other technologies.

· Large-size processing: Can handle workpieces up to several meters long.

· Welding: Carbon steel, stainless steel, and aluminum alloys (requires special welders/processes like MIG/TIG) are most common.

· Riveting/Screwing: Works for almost all combinations of metal sheets that can be drilled/tapped.

· Strong and reliable: Welding forms a permanent, high-strength connection.

· Highly automated: Robotic welding ensures high efficiency and stable quality.

· Good sealing: Can meet airtight and watertight requirements (e.g., fuel tanks, water tanks).

· Strong adaptability: Can connect metal parts of different thicknesses and shapes.

· Comprehensive processes: Proficient in welding various materials (stainless/carbon steel, aluminum) with continuous, intermittent, spot, and TIG welding.

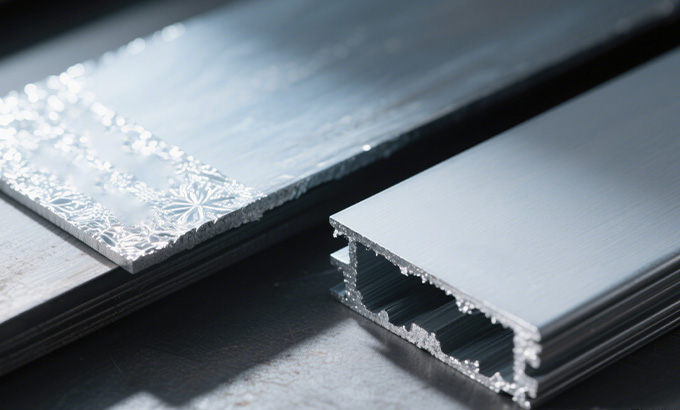

Applicable Metals: Aluminum, copper, stainless steel, etc.

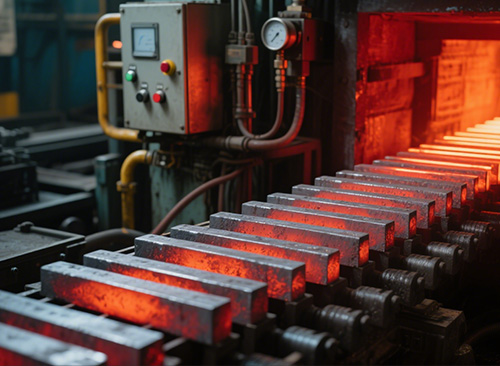

· High-efficiency mass production: Continuous automated processing is fast, suitable for large-volume production, and low cost.

· Stable precision: Cross-section dimensional tolerance within ±0.1mm, good straightness, and reduced springback deviation.

· Wide material adaptability: Cold work hardening can improve hardness and fatigue resistance.

· Flexible design: Can form complex cross-sections (e.g., C-shaped steel, special-shaped grooves), and changing rollers allows for shape adjustment with low modification costs.

Steel, stainless steel, aluminum, copper, etc.

· High-precision processing, suitable for complex geometric shapes.

· Can perform multi-directional processing, with high precision and surface quality.

· High finish.

Our engineers provide material recommendations based on your product's function, environment, budget, and appearance.

We offer various surface treatments to enhance corrosion resistance, durability, appearance, and function.

![]()

Painting/Powder Coating

![]()

Electroplating

![]()

Brushing/Polishing

![]()

Anodizing

![]()

Hot-dip Galvanizing

![]()

Passivation/Phosphating

![]()

Sandblasting

![]()

Carburizing

Our custom sheet metal services comply with ISO 2768-m to ensure precision and functionality.

| Dimension Details | Metric Units | Imperial Units |

|---|---|---|

| Edge to edge, single surface | ±0.127 mm | ± 0.005 in |

| Edge to hole, single surface | ±0.127 mm | ± 0.005 in |

| Hole to hole, single surface | ±0.127 mm | ± 0.005 in |

| Bend to edge/hole, single surface | ±0.254 mm | ±0.010 in |

| Edge to feature, multiple surfaces | ±0.762 mm | ± 0.010 in |

| Overmolded part, multiple surfaces | ±0.762 mm | ± 0.030 in |

| Bend Angle | ± 1° | |

Sharp edges are deburred by default. Specify on your drawing if an edge must remain sharp.

Upload Drawing